High-Performance Shock Rebuild Tools

Below is a list of parts and tools needed for servicing, tuning, and rebuilding King, Fox, ADS, Radflo and other high-performance shocks. For detailed instructions on how to service shocks, see our Shock Rebuild Instructions

Many of the links and photos on this page are links to Amazon so they may not be visible if you have an ad blocker running.

Crawlpedia earns a small commission on Amazon purchases which does not affect your pricing and allows us to keep this web site in operation.

Assemble a Nitrogen Fill-Kit:

Put together your own Nitrogen Fill Kit with a pressure regulator, connection hose, and an air chuck or no-loss air chuck. The only other item needed is a nitrogen tank that is available at any local welding supply shop.

Recommended Tools for High-Performance Shock Service:

To perform a proper shock rebuild, you will need some basic hand tools including wrenches and sockets, however, some less common tools like spanner wrenches and snap ring pliers will also be required. Below you will find some Amazon links to the exact same tools we currently use for service work.

1. A Spanner Wrench

The most important tool for servicing race shocks that many people don't have is a proper spanner wrench. For King 2.0 a 2.5 shocks you will need a spanner wrench with a wide opening and 3/16" pins like this Stanley Proto JC482 Spanner Wrench, or if you wanted to purchase a more universal spanner wrench, consider this OTC 6613 Variable Pin Spanner Wrench.

2. High Quality Snap Ring Pliers

The next most important tool for shock servicing is a high quality pair of snap ring pliers. While any basic set of snap ring pliers will ultimately work, a heavier duty set of pliers like these Knipex Angled C-Clip Pliers will get the job done easier and safer.

3. Safety Glasses and Gloves

A

s with all service work, make sure you have a good set of safety glasses and gloves. They are cheap and will save your eyes and hands. For safety glasses, we always buy in bulk so if a pair goes missing you always have plenty more to pull from and so there is no excuse to not be wearing them. We like these Bison Life Safety Glasses (12 Pack) and for gloves we've been loving these Gloveworks HD Nitrile Gloves at the shop.

4. Shop Rags and Paper Towels

Any time you work on shocks, expect to get oil everywhere and on everything so be prepared with plenty of paper towels or, better yet, buy a bunch of cheap and disposable Shop Rags.

5. Hammers Large and Small

For servicing off-road racing shocks you'll want to have 3 different types of hammers available. First, a small hammer with non marring ends like this Marketty Hammer with 4 Interchangeable Heads. Additionally, you will want to have a dead blow hammer like this Neiko 2 lb. Dead Blow Hammer. Finally, in some cases, you will find yourself needing a 3-6 lb. small sledge hammer like this Estwing 3lb. Fiberglass Sledge Hammer.

6. Vice and Vise Jaw Pads

During service, a vice is used to hold the shock cylinder vertical. A shop rag can be used to protect your shocks, although, we highly recommend a set of soft jaws. There are a lot of soft jaws available and we've tried them all but found that these Magnetic Vice Jaw Covers from Workpro have been our favorites. As for the vice, it is really nice to have two, a small one to hold the shock during service and a larger one to use for pressing in bearings and seals. Ultimately, though, for most people, a single multi-purse vice will get the job done. They can be purchased cheap at any local hardware store but we consider a good vice to be a lifelong investment so it really is worth saving up for a Wilton Vice.

7. Picks and Hooks

Removing o-rings and seals from a shock can be done with a small flathead screwdriver but a set of picks like this Ullman Devices Hook and Pick Set make the job a lot easier. Tip: We grind down the tips of a few picks to round their ends for removing o-rings from aluminum components to prevent scratches.

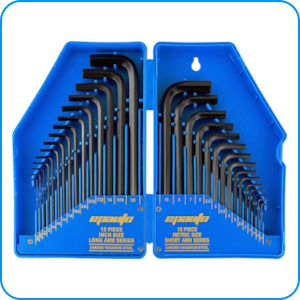

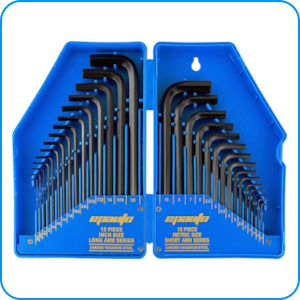

8. Allen Wrenches

Almost all screws on a high performance shock will be socket head cap screws requiring allen wrenches to remove and tighten them. Some of the screws are quite small so most basic allen wrench kits will not have all that you need but we found this EPAuto Allen Key Set that has them all. If you would prefer to purchase high quality individual allen wrenches, they are listed below:

9. Nitrogen Fill Kit

To pressurize the shock reservoirs, you will need a Nitrogen Fill Kit made up of a pressure regulator, connection hose, and an air chuck or no-loss air chuck. The only other item needed is a nitrogen tank that is available at any local welding supply shop.

10. Pressure Gauge

Checking reservoir pressure on a shock requires a 300 PSI gauge. We use a Winters 300 PSI Pressure Gauge with a 1/4" NPT Tire Chuck (with some Teflon tape on the treads).

11. Piston Bleed Screws

Set screws are used to plug bleed holes during tuning so it's always good to have them on hand. We suggest picking up a pack of 4-40 x 1/8" Set Screws for King 2.5 PR series shocks and/or 8/32 x 1/4" Set Screws for King 3.0 PR and RS series shocks. King 2.0 shocks do not have threaded bleed holes but they can be drilled and tapped if needed.

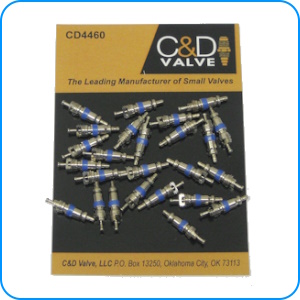

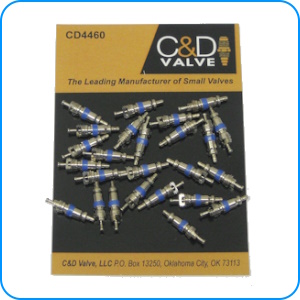

12. Schrader Valve Caps and Cores

It is very common for schrader valve caps to go missing, not just on shocks but also on tires so it's always a good idea to keep plenty of quality valve caps on hand. Our favorites are these Valve-Loc Aluminum Valve Caps. In addition to valve caps, be sure to pick up a set of Teflon Seal Schrader Valve Cores. The primary cause of pressure loss is a loose or damaged valve core so when in doubt, replace them.

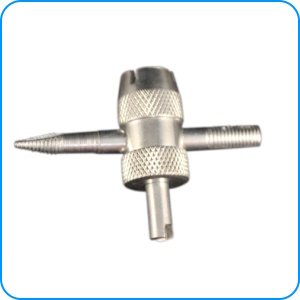

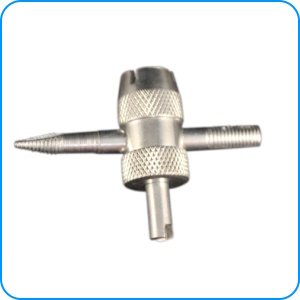

13. Valve Core Tool

A valve core tool like this Milton 4-in-1 Valve Core Tool is essential for servicing shocks. One end is used to tighten, remove, or install valve cores, another threads over the stem for end cap removal, the third allows for easy bleeding, and the fourth side cleans the valve core threads. Tip: Attach a Dually Valve Core Extension for extended reach inside the reservoir.

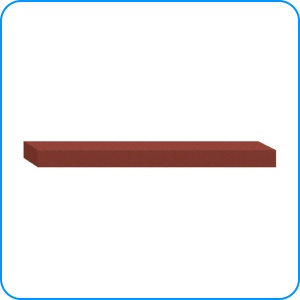

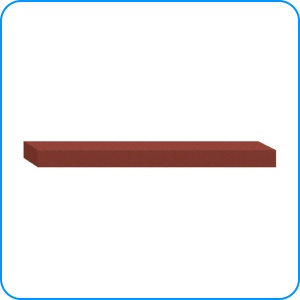

14. Abrasive Blocks (Emery Sticks)

To polish up scratches or imperfections on shock shafts, seal heads, and IFPs, you will need a few rubberized abrasive blocks, also known as emery sticks or emery blocks. The two that we always keep on hand are a Dedeco Extra Fine Rubberized Abraisive Block and a Dedeco Fine Rubberized Abrasive Block. Tip: Use a utility knife to shave the blocks down to specific shapes to get into o-ring grooves and around shock shafts.

15. Loctite / Threadlocker

When rebuilding shocks it is very important to have some threadlocking compound on hand to make sure that components like shaft nuts, rod ends, and top caps stay in place. We recommend Loctite 243 Blue Medium Threadlocker.

16. IFP Setting Tool

To remove, install, and set the depth of the reservoir IFP (internal floating piston), you will need a specific tool. While these tools are available from other vendors, they are easy and cheap to make yourself. All you need is a 1/4"-20 Threaded Rod and a 1/4"-20 Plastic Knob. Use some Loctite or a jam nut to keep the knob at the end of the rod and you are all set. Take it one step further by puttin a few layers of 1/2" Heat Shrink over the threads to prevent accidental contact with the reservoir.

17. Bearing Lubricant

If the bearings on the shocks you are servicing fell tight and not yet in need of replacing, put a few drops of Tri-Flow PTFE Lubricant between the ball and race to extend their usable life. This stuff is also great and highly recommended for periodic maintenance.

18. 24" Adjustable Wrench

Some parts like shock top caps and shaft rod ends take a lot of force to remove so for those items you will need an extra-large 24" Adjustable Wrench. Tip: Wrap masking tape around the jaws to prevent scratching the shock components.

19. Propane Torch

To loosen and remove components that have been previously assembled with threadlocker like top caps and rod ends, or parts that have been heavily corroded or seized, you will need to use some heat. Be sure to have a Berzomatic Trigger Start Torch and some Propane Canisters available.

20. Penetrant and Lubricant

Prior to working on any used shocks we always spray some penetrant on the exposed bolts to give us the best chance of removing them. We like to use CRC Screwloose Super Penetrant but of course WD-40 works great, too.

21. Caliper

Measuring shock parts to order replacements requires accuracy which is why you will need to use a caliper like this Digital 0-6" Metric/Inch Caliper with Fractions. Never use a tape measure as most shock parts are imperial (inch) while some misalignment spacers may have metric inner diameters and only a caliper is accurate enough to measure correctly.

22. Preload Pin / Punch

For adjusting preload on coilvoers, a steel punch like this Mayhew Select 5/16-Inch Pin Punch works great and is cheaper than most brand specific preload adjustment tools. For IFS and other high spring rate applications, consider using two pins together to distribute the adjustment forces. We have found that 5/16" and 8mm punches work great for 2.5" King coilovers but please confirm sizing on your coilovers before ordering.

23. 1/2" Heat Shrink

If your reservoirs are mounted with traditional hose clamps, slip some 1/2" Heat Shrink tubing over the clamps for a cleaner looking installation.

As an Amazon Associate, we earn a small commission on purchases which does not affect your pricing.

This shock tool guide is ©Copyright Crawlpedia.com - Please provide a link back to this page when copying.

Data is accurate to the best of our knowledge and is offered as-is with no guarantee.

More Shock Guides:

Shock Rebuild Instructions - Detailed step-by-step instructions for rebuilding high-performance shocks.

Shock Valving Guide - A guide to high-performance shock valving and valving shim configurations.

Shock Tuning Guide - A guide to how high-performance shocks are tuned and valved to work well.

Shock Valving Shim Stack Examples - A list of common, basic valving shim stack configurations for high-performance shocks.

Coilover Spring Rate Calculator - A calculator to help you determine a good starting point for coilover spring rates.

4-Link Suspension Guide - A quick overview of the most important elements of 4-link geometry.

Shock Rebuild Parts - A link to Filthy Motorsports' shock parts page.

How To Measure For Coilovers - Order the right size shocks and coilovers by following these detailed instructions.

Coilover Install and Setup Guide - Proper coilover installation, setup, and fine tuning instructions.

Coilover Spring Re-Calculation Guide - How to easily correct coilover spring rates to achieve your desired ride height.

ORI STX Struts Guide - An introduction to ORI STX Struts, how they work and how to tune them.

Hydraulic Bump Stop Guide - A detailed overview of hydraulic bump stops and jounce shocks for off-road use.

Filthy Motorsports

High performance off-road racing parts and professional shock tuning. Learn more at

FilthyMotorsports.com

Shock Service, LLC

Professional shock tuning and rebuilding services for King and ADS shocks. Learn more at

ShockService.com

Polar Cryogenics

Cryogenic treatment improves strength and longevity of gears, axle, and brakes. Learn more at

PolarCryogenics.com

Crown Race Gears

Race-spec ring and pinion gears for desert racing, rock bouncing, and rock crawling. Learn more at

RaceGears.com