Coilover Install & Setup Guide

Coilover shocks come in many different brands, sizes and configurations, however, the setup and installation is the same for all coilovers and this guide will walk you through that process.

Coilovers ship in several different ways. They will either ship charged (fully extended) or uncharged (collapsed), and with either the springs installed or included separately. The coilovers in the above photo are already charged with nitrogen and have both springs installed.

Upon receiving your coilovers, the first thing you should do is inspect them carefully, make sure they are the correct size, and if needed, verify which set is for the front of the vehicle and which ones are for the rear. King includes shock specifications on green tags attached to each shock.

Step 1: Install the Springs and Set Preload

If your coilovers are delivered without springs installed, the first step is to add them. To do this, start by fully extending the shock by pulling on the shaft by hand. Then, if the lower spring plate came installed on the lower rod end, remove it by lifting it up and sliding it out through the slot over the shaft. (Some shocks use other spring plate designs, but sliding them up will always reveal the seating mechanism.)

If your coilovers are delivered without springs installed, the first step is to add them. To do this, start by fully extending the shock by pulling on the shaft by hand. Then, if the lower spring plate came installed on the lower rod end, remove it by lifting it up and sliding it out through the slot over the shaft. (Some shocks use other spring plate designs, but sliding them up will always reveal the seating mechanism.)

Install the first spring by sliding it up the shaft until it contacts the upper spring retainer (coil adjustment / pre-load nut). Remember, the lighter rate and/or shorter spring always goes on first. For dual rate coilovers, the next item to go on is the slider followed by the lower spring. Triple rate coilovers will have the tender spring already installed at the top as that goes on during the assembly process to put it above the stop nuts.

Finally, install the lower spring plate by sliding it through the shock shaft and down onto the lower rod end. Some coilover brands use slightly different designs but this is the most common.

Important: If your coilovers have a rubber or foam bump stop on the shaft, the lower spring plate must go under the bump stop (between the bump stop and the lower rod end). The lower spring plate must sit directly and securely on the lower rod end of the coilover at all times.

A coilover with the same rate springs top and bottom still provides a dual-rate transition. For example, a 200/200 combination will act as 100 primary / 200 secondary. If the spring rates are different, the lighter and often shorter spring always goes on top. For more information on spring rates see Spring Rate Calculator and Spring Re-Calculation Guide.

If the lower spring plate won't fit onto the shaft, make sure that the upper coil adjuster nut has been rotated all the way to the top of the shock and try again. If the lower spring plate still doesn't fit, you may need to compress the springs slightly to give yourself room. For lighter springs, this can be done with tie down straps and heavier springs will require a coil spring compressor.

With the lower spring plate installed, rotate your upper spring retainer (coil adjustment nut) down by hand until the springs are snug together and then double check to make sure that the lower spring plate is properly seated on the lower rod end. This position will be your zero-preload position and it should never be adjusted any higher than this so we recommend making a mark on the threads here for reference. If the coil adjustment nut has a locking screw, it is important to tighten it down after any changes.

With your springs installed and adjusted to zero preload, you should not see more than about 3" of threads above the coil adjustment nut (16" and 18" coilover may have more). If you do, there is a good chance you will need longer springs but for the time being they should be good enough for the initial installation and setup. At this point you are ready to move on to installing the coilovers on the vehicle.

Define Preload: Pre-Load is how much the springs have been compressed as mounted on a fully extended coilover. If a 16" free height coil spring is installed and measures 14" we would say it has 2" of preload. Zero pre-load is the point at which the springs, slider, spring plate, and coil nut adjusters are touching with no play. The amount of threads showing above the coil nut adjuster is NOT that same as pre-load.

Step 2: Install the Coilovers and Check Your Springs

Safety First! Installing coilovers on the vehicle for the first time can be dangerous so be careful. This will require lifting the vehicle high up where it will be unstable and this will also be the first time that your upper and lower coilover mounts will be tested under the full weight of the vehicle so make sure to support the vehicle with jack stands, wear eye and ear protection, go slowly, be vigilant, and use common sense. If you have any hesitations at all, have a professional help you with this process. Finally, make sure to only use grade 8 or higher bolts, lock washers, and nuts.

It is also highly recommended to "dry fit" (no springs installed, no pressure in the reservoirs) your coilovers and fully cycle the suspension to check for clearances, binding, component contact, and confirm full compression and full extension positions prior to installing the coilovers for the first time.

With the vehicle chassis suspended and the suspension at full droop, install the coilovers using grade 8 bolts, lock washers, and nuts. Check for clearances around the coilovers and then, very slowly, start lowering the weight of the vehicle down onto them.

Hopefully, once the weight of the vehicle is entirely resting on the coilovers, it is settled at or slightly below your desired ride height. If not, then you will need to make one of the following spring and/or pre-load adjustments:

Hopefully, once the weight of the vehicle is entirely resting on the coilovers, it is settled at or slightly below your desired ride height. If not, then you will need to make one of the following spring and/or pre-load adjustments:

A. Vehicle Sits 1 to 3 Inches Below Ride Height:

If, under the full weight of the vehicle, your springs settle 1 to 3 inches below the desired ride height, then you will simply need to add that amount of pre-load to your coilovers.

B. Vehicle Sits More than 3 Inches Below Ride Height:

If the coilovers settle more than 3 inches below your desired ride height, or are fully collapsed, then you will need to change your springs. Please see our

Coilover Spring Re-Calculation Guide to find the proper spring rates based on calculations from your existing springs.

C. Vehicle Sits Above Ride Height:

If under its final, wet, loaded, running weight, the vehicle sits above your desired ride height, then you will need to change your springs. See our

Coilover Spring Re-Calculation Guide to find the proper spring rates based on calculations from your existing springs.

Important Tips: New shocks have very tight seals that will cause the coilovers to "stick" in different positions. This goes away when the shocks are warmed up so be sure to make your final changes during your first testing session. It is also normal for coilovers to require different amounts of pre-load on each corner due to different corner weights. Finally, remember that adding people, gear, and fuel will cause the coilovers to settle a bit more so take that into account during your pre-load adjustments.

How to Add Pre-Load on a Coilover

To add pre-load to your coilover springs, remove all weight from the springs by lifting the vehicle's chassis and letting the suspension droop out. Then, using a coil nut adjusting tool (we like to use a screwdriver with a nice handle that we have cut down), rotate the upper coil adjustment nut down the desired distance. Using a lubricant like WD-40 on the threads is also recommended. If the coil adjustment nut uses a locking screw, make sure to loosen it before making an adjustment and then tighten it down when you are done. With the preload adjustments made, slowly release the vehicle weight down onto the coilovers again. Hopefully, the vehicle is now settled at your desired ride height. If not, follow the above steps again as needed.

To add pre-load to your coilover springs, remove all weight from the springs by lifting the vehicle's chassis and letting the suspension droop out. Then, using a coil nut adjusting tool (we like to use a screwdriver with a nice handle that we have cut down), rotate the upper coil adjustment nut down the desired distance. Using a lubricant like WD-40 on the threads is also recommended. If the coil adjustment nut uses a locking screw, make sure to loosen it before making an adjustment and then tighten it down when you are done. With the preload adjustments made, slowly release the vehicle weight down onto the coilovers again. Hopefully, the vehicle is now settled at your desired ride height. If not, follow the above steps again as needed.

Important Note: Never adjust your pre-load with the weight of the vehicle on the coilovers, this can damage the coilover cylinder and/or the coil nut, both of which are expensive and hard to replace.

Pressurize the Coilovers to 150 PSI

If your coilovers shipped uncharged (collapsed), or if you discharged them to make the installation process easier, now is the time to pressurize the shock with nitrogen. While different brands of performance shocks and coilovers have recommended pressures of 100 to 250 PSI, we find that 150PSI is a great place to start across the board.

Use Nitrogen, Not Compressed Air The most common question we get about charging shocks is if it is okay to use shop air instead of Nitrogen. While compressed air will effectively pressurize the shock, it will also introduce moisture into the shock which may cause the retaining rings to rust or seize. Nitrogen also holds constant pressure much better and is less affected by increases in shock temperature.

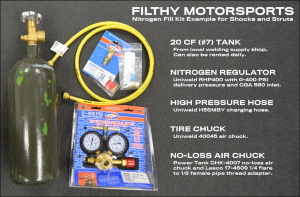

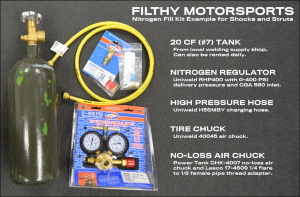

To assemble a nitrogen fill kit, you will need a nitrogen tank, a 400+ PSI regulator, connection hose, and an air chuck. These parts can all be sourced, or often times rented daily from any local welding supply shop.

Assemble a nitrogen fill kit with these parts from Amazon.

Put together your own Nitrogen Fill Kit with a pressure regulator, connection hose, and an air chuck or no-loss air chuck. The only other item needed is a nitrogen tank that is available at any local welding supply shop.

As an Amazon Associate, we earn a small commission on purchases which does not affect your pricing.

Step 3: Initial Test Run

With the coilovers mounted on the vehicle and the proper springs and pre-load set, it is time to go for an initial test run. While this guide does not cover shock valving or shock tuning, the initial test run will give you an initial feel for both. Ultimately, as far as your springs are concerned, you simply need them to be as light as possible, yet strong enough for them to support the vehicle without requiring excessive pre-load, so if you followed the above instructions, you are all set.

Important Note: Coilovers should not be used to fix body lean or sway. If the vehicle has excessive body roll during testing, you will either need to add a sway bar or adjust your suspension geometry and coilover positions (or both). Please make sure to review our 4-Link Suspension Guide.

Step 4: Set Your Stop Nuts

On dual rate and triple rate coilovers, the last thing you will need to adjust are your stop nuts. The stop nuts are threaded onto the cylinder below the coil adjustment nut and are used to set the transition point between the primary rate (a combination of teh upper and locer springs) and the lower spring (secondary rate).

On dual rate and triple rate coilovers, the last thing you will need to adjust are your stop nuts. The stop nuts are threaded onto the cylinder below the coil adjustment nut and are used to set the transition point between the primary rate (a combination of teh upper and locer springs) and the lower spring (secondary rate).

For most applications, the stop nuts should be positioned about 1 to 3 inches above the slider (spring separator) when the vehicle is at ride height. This means that the first 1 to 3 inches of up travel will be on the softer spring rate and after that it will transition to the lower spring rate.

To move the stop nuts, use a flat screwdriver and a hammer to knock the upper nut up (spin to the right) and the lower nut down (spin to the left), some coilover brands use a rubber o-ring between the stop nuts to lock them in place so make sure not to damage it. Spin the stop nuts to their new position and then tighten them against each other and give them each a moderate tap with the screwdriver and hammer.

Fine Tuning

Now that your coilover springs are set up correctly, it's time to do more testing and tuning. If you've followed the instructions above, then your spring rates are correct, and any changes moving forward should be small and incremental. The following is a quick list of adjustment you may need to make:

- Add or remove pre-load to change your ride height. Never go above your zero preload point and never go beyond 4" of preload.

- Adjust your stop nuts to change where your spring rate transitions.

This coilover setup guide is ©Copyright Crawlpedia.com - Please provide a link back to this page when copying.

Data is accurate to the best of our knowledge and is offered as-is with no guarantee.

More Shock Guides:

Shock Rebuild Instructions - Detailed step-by-step instructions for rebuilding high-performance shocks.

Shock Rebuilding Tools - A list of tools needed to service high-performance shocks and coilovers.

Shock Valving Guide - A guide to high-performance shock valving and valving shim configurations.

Shock Tuning Guide - A guide to how high-performance shocks are tuned and valved to work well.

Shock Valving Shim Stack Examples - A list of common, basic valving shim stack configurations for high-performance shocks.

Coilover Spring Rate Calculator - A calculator to help you determine a good starting point for coilover spring rates.

4-Link Suspension Guide - A quick overview of the most important elements of 4-link geometry.

Shock Rebuild Parts - A link to Filthy Motorsports' shock parts page.

How To Measure For Coilovers - Order the right size shocks and coilovers by following these detailed instructions.

Coilover Install and Setup Guide - Proper coilover installation, setup, and fine tuning instructions.

ORI STX Struts Guide - An introduction to ORI STX Struts, how they work and how to tune them.

Hydraulic Bump Stop Guide - A detailed overview of hydraulic bump stops and jounce shocks for off-road use.

Filthy Motorsports

High performance off-road racing parts and professional shock tuning. Learn more at

FilthyMotorsports.com

Shock Service, LLC

Professional shock tuning and rebuilding services for King and ADS shocks. Learn more at

ShockService.com

Polar Cryogenics

Cryogenic treatment improves strength and longevity of gears, axle, and brakes. Learn more at

PolarCryogenics.com

Crown Race Gears

Race-spec ring and pinion gears for desert racing, rock bouncing, and rock crawling. Learn more at

RaceGears.com

If your coilovers are delivered without springs installed, the first step is to add them. To do this, start by fully extending the shock by pulling on the shaft by hand. Then, if the lower spring plate came installed on the lower rod end, remove it by lifting it up and sliding it out through the slot over the shaft. (Some shocks use other spring plate designs, but sliding them up will always reveal the seating mechanism.)

If your coilovers are delivered without springs installed, the first step is to add them. To do this, start by fully extending the shock by pulling on the shaft by hand. Then, if the lower spring plate came installed on the lower rod end, remove it by lifting it up and sliding it out through the slot over the shaft. (Some shocks use other spring plate designs, but sliding them up will always reveal the seating mechanism.)

Hopefully, once the weight of the vehicle is entirely resting on the coilovers, it is settled at or slightly below your desired ride height. If not, then you will need to make one of the following spring and/or pre-load adjustments:

Hopefully, once the weight of the vehicle is entirely resting on the coilovers, it is settled at or slightly below your desired ride height. If not, then you will need to make one of the following spring and/or pre-load adjustments: To add pre-load to your coilover springs, remove all weight from the springs by lifting the vehicle's chassis and letting the suspension droop out. Then, using a coil nut adjusting tool (we like to use a screwdriver with a nice handle that we have cut down), rotate the upper coil adjustment nut down the desired distance. Using a lubricant like WD-40 on the threads is also recommended. If the coil adjustment nut uses a locking screw, make sure to loosen it before making an adjustment and then tighten it down when you are done. With the preload adjustments made, slowly release the vehicle weight down onto the coilovers again. Hopefully, the vehicle is now settled at your desired ride height. If not, follow the above steps again as needed.

To add pre-load to your coilover springs, remove all weight from the springs by lifting the vehicle's chassis and letting the suspension droop out. Then, using a coil nut adjusting tool (we like to use a screwdriver with a nice handle that we have cut down), rotate the upper coil adjustment nut down the desired distance. Using a lubricant like WD-40 on the threads is also recommended. If the coil adjustment nut uses a locking screw, make sure to loosen it before making an adjustment and then tighten it down when you are done. With the preload adjustments made, slowly release the vehicle weight down onto the coilovers again. Hopefully, the vehicle is now settled at your desired ride height. If not, follow the above steps again as needed.

On dual rate and triple rate coilovers, the last thing you will need to adjust are your stop nuts. The stop nuts are threaded onto the cylinder below the coil adjustment nut and are used to set the transition point between the primary rate (a combination of teh upper and locer springs) and the lower spring (secondary rate).

On dual rate and triple rate coilovers, the last thing you will need to adjust are your stop nuts. The stop nuts are threaded onto the cylinder below the coil adjustment nut and are used to set the transition point between the primary rate (a combination of teh upper and locer springs) and the lower spring (secondary rate).